Additive manufacturing in aluminium of a primary mirror for a CubeSat application: manufacture, testing, and evaluation

Written by: Ilhan Aziz et al. Published on:

Published on: Summary

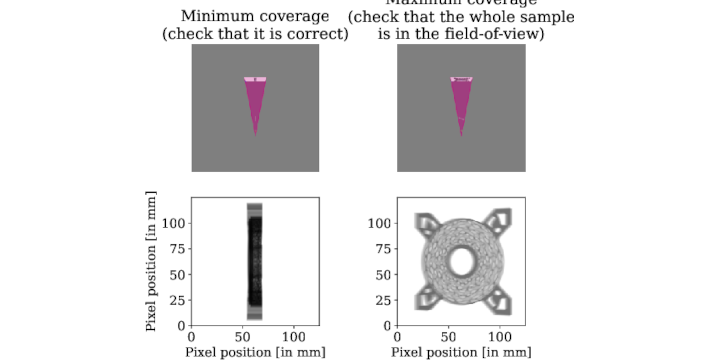

Additive manufacturing (AM; 3D Printing), a process which creates a part layer-by-layer, has the potential to improve upon conventional lightweight mirror manufacturing techniques, including subtractive (milling), formative (casting) and fabricative (bonding) manufacturing. Increased mass reduction whilst maintaining mechanical performance can be achieved through the creation of intricate lattice geometries, which are impossible to manufacture conventionally. Further, part consolidation can be introduced to reduce the number of interfaces and thereby points of failure. AM design optimisation using computational tools has been extensively covered in existing literature. However, additional research, specifically evaluation of the optical surface, is required to qualify these results before these advantages can be realised. This paper outlines the development and metrology of an AM mirror for a CubeSat platform with a targeted mass reduction of 60% compared to an equivalent solid body. This project aims to incorporate recent developments in AM mirror design, with a focus on manufacture, testing and evaluation. This is achieved through a simplified design process of a Cassegrain telescope primary mirror mounted within a 3U CubeSat chassis. The mirror geometry is annular with an external diameter of 84 mm and an internal diameter of 32 mm; the optical prescription is flat for ease of manufacture. Prototypes were printed in AlSi10Mg, a low-cost aluminium alloy commonly used in metal additive manufacturing. They were then machined and single-point diamond turned to achieve a reflective surface. Both quantitative and qualitative evaluations of the optical surface were conducted to assess the effect of hot isostatic pressing (HIP) on the optical surface quality. The results indicated that HIP reduced surface porosity; however, it also increased surface roughness and, consequently, optical scatter.

Publication

Ilhan Aziz, Younes Chahid, Jennifer Keogh, James Carruthers, Katherine Morris, Joel Harman, Scott McPhee, Eilidh Fraser, Luca Millan, Cyril Bourgenot, Paul White, Spencer H. Davies, Franck P. Vidal, Wenjuan Sun, Mirko Sinico, Fraser Laidlaw, Wai Jue Tan, Arindam Majhi, and Carolyn Atkins (2025, Aug). Additive manufacturing in aluminium of a primary mirror for a CubeSat application: manufacture, testing, and evaluation. SPIE Optics + Photonics 2025, Astronomical Optics: Design, Manufacture, and Test of Space and Ground Systems V, 4 – 7 August 2025 in San Diego, CA, USA. Vol. 13624. doi:10.1117/12.3063056 .

Citation

@inproceedings{10.1117/12.3063056,

author = {Aziz, Ilhan and Chahid, Younes and Keogh, Jennifer and Carruthers, James and

Morris, Katherine and Harman, Joel and McPhee, Scott and Fraser, Eilidh and

Millan, Luca and Bourgenot, Cyril and White, Paul and Davies, Spencer and

Vidal, Franck P. and Sun, Wenjuan and Sinico, Mirko and Laidlaw, Fraser and

Tan, Wai Jue and Majhi, Arindam and Atkins, Carolyn},

booktitle = {{Astronomical Optics: Design, Manufacture, and Test of Space and Ground Systems V}},

editor = {Hull, Tony B. and Kim, Daewook and Hallibert, Pascal},

keywords = {Mirror fabrication; Lightweight mirrors; Additive manufacturing; Aluminium; Design optimisation; Lattice structures; Surface characterisation; Optical metrology},

organization = {International Society for Optics and Photonics},

pages = {136241Y},

publisher = {SPIE},

title = {{Additive manufacturing in aluminium of a primary mirror for a CubeSat application: manufacture, testing, and evaluation}},

doi = {10.1117/12.3063056},

volume = {13624},

year = {2025}

}